Large Format Printing | Custom Wide-Format Production

Want your message to go further and your brand to stand out? At Craftsmen Industries, we specialize in large-format printing and custom wide-format production, turning blank walls, storefronts, windows, vehicles, and venues into bold, unforgettable statements.

And because out-of-home visuals are hard to ignore, more than 9 in 10 U.S. travelers notice OOH advertising each month (and 8 in 10 each week), underscoring how large-scale graphics consistently capture real-world attention.

Backed by decades of experience, in-house expertise, and precision technology, we deliver vibrant, durable graphics at any scale, on time, and with craftsmanship you can trust.

Why Trust Craftsmen Industries for Wide-Format Printing?

Work with a team that's just as invested in your project as you are. We combine deep experience, hands-on craftsmanship, and cutting-edge print technology to help your brand truly stand out.

Decades of Proven Experience

With over 40 years of hands-on experience, Craftsmen Industries has helped brands and organizations nationwide create show-stopping graphics, everything from stadium banners and building wraps to detailed event installations. Our deep knowledge means fewer surprises and more innovative solutions, no matter the challenge.

All Under One Roof

Enjoy the convenience of a single trusted partner. We handle every stage, from artwork preparation to printing, finishing, and installation, in our own advanced facility. This approach ensures tighter quality control, faster turnaround times, and a truly seamless experience from start to finish.

Color That Pops, Quality That Lasts

We use G7-certified color management and the latest printing technology to deliver rich, accurate color on every job, whether you need one graphic or thousands.

Stress-Free Project Coordination

Craftsmen's experienced project managers coordinate every detail, from the first site survey to final installation. We handle logistics, scheduling, and technical requirements, so your project stays on track and stress-free, letting you focus on your bigger business goals.

Contact us to find out how Craftsmen

can turn your branding dream into a reality

or Call Today 800.373.3575

Full-Service In-House Graphics Department

Full-Service In-House Graphics Department

"If you want to build the impossible, Craftsmen has the tools and talent. They are more like a Venture partner than a builder."

Founder & CEO

Magicbox

Magicbox

"Craftsmen, hands down, had the best ideas, best drawings. They were as passionate about the project as I was. I don't know why anyone would go anywhere else."

PGA Tour Technician

TaylorMade

TaylorMade

"High caliber work, great crew of talented workers who come up with creative solutions and are easy to work with, overall great partners."

Creative Director

Dairy Farmers of America

Dairy Farmers of America

"The team at Craftsmen is top notch and they always get the job done no matter the deadline. I consider them an extension of our team - a true partner!"

Executive Director

Clayco

Clayco

What Makes Our Large Format Printing Different?

Our approach to wide-format printing combines advanced technology, real-world experience, and a commitment to every detail, so your graphics always stand out and perform.

State-of-the-Art Print Technology

We invest in the latest wide-format printing equipment, producing crisp, high-resolution results on a wide range of materials: vinyl, fabric, acrylic, aluminum, rigid board, mesh, and more.

Versatile Solutions for Any Project

Whether you need a massive building wrap, a branded fleet, or custom displays for retail, our facility is equipped to handle everything from single oversized prints to complex, multi-piece installations.

Precision Finishing

We know that how your graphics are finished matters. Our team provides expert cutting, mounting, lamination, hemming, grommets, and hardware, delivering a polished, professional product every time.

Built for Durability

Your graphics shouldn't just look good on day one. We use proven processes and materials to ensure durability and colorfastness, indoors or out, no matter the weather.

Professional Installation

Let our certified installers manage the final step. We make sure every piece is expertly installed and fits perfectly, whether it's for a stadium, a lobby, a storefront, or a public space.

Discover Our Wide-Format Printing Solutions

Our advanced printing solutions put your message where people will see it, feel it, and remember it, so your brand makes the impact it deserves

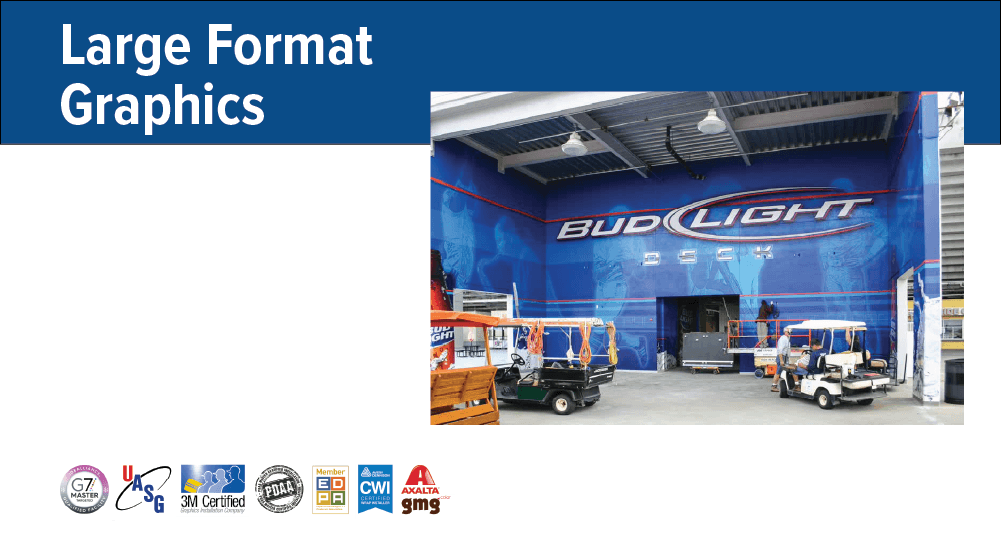

Wall Murals & Environmental Graphics

Turn blank walls into bold statements. We design and print custom murals and experiential graphics for interiors and exteriors, helping you share your story and energize every space.

Window & Glass Graphics

Make the most of every surface. Our custom window and glass graphics add privacy, deliver branded messaging, and showcase full-color visuals using frosted, perforated, or transparent films, all tailored to your exact needs.

Banners, Mesh, & Building Wraps

Go big, indoors or out. Our banners, mesh wraps, and building graphics are engineered for maximum visibility, durability, and wind resistance, delivering attention-grabbing results in any environment.

Vehicle & Fleet Graphics

Research shows that vehicle graphics generate 30,000-70,000 impressions per day, 64% of people surveyed noticed them, and that’s precisely why we help your brand expand its reach. Whether it’s a single service van or an entire national fleet, our custom wraps and decals transform vehicles into moving advertisements that turn heads wherever they go.

Retail, Event & POP Displays

Stand out where it matters most. From point-of-purchase displays to event backdrops and custom signage, we print and fabricate solutions that command attention and drive engagement at every touchpoint.

Stadium & Arena Graphics

Bring energy to large venues with stadium graphics. We handle everything from seating wraps and sponsor signage to wayfinding and concourse graphics, ensuring your venue is both functional and unforgettable.

We Offer Customization Options to Fit Your Vision

Every project is unique, and so are the options we offer. With a full range of materials, finishes, and creative enhancements, we make it easy to achieve the look, feel, and performance your space demands.

Wide Range of Substrates

Pick the right foundation for your graphics. We offer premium vinyls, high-quality fabrics, rigid boards, acrylic, foam, mesh, and more, so you get the ideal match for your environment and budget.

Advanced Color Matching

Consistent, accurate color is always a priority. Our G7-certified color process ensures your branding looks sharp and stays true, print after print.

Specialty Finishes

Give your graphics extra impact and protection. Choose from gloss or matte lamination, anti-graffiti coatings, metallic or textured effects, and precise die-cut shapes for a look that lasts.

Integrated Lighting & Interactive Elements

Add extra dimension and visibility. We can incorporate backlighting, illuminated displays, or even digital and interactive features to help your message stand out day or night.

Kitting & Nationwide Shipping

Make multi-location rollouts simple. We pre-pack and ship complete graphics kits directly to your sites, ensuring coordinated, efficient, hassle-free installations.

How Our Large Format Printing Process Works

Every stage of our process is built on quality, clear communication, and efficiency, ensuring your project moves smoothly from start to finish.

Step 1: Consultation

We start by listening. Our team reviews your project goals, measurements, site requirements, and branding guidelines to recommend the best print solutions for your needs.

Step 2: Artwork Preparation & Proofing

Send us your artwork, or let us help you design it. We prepare proofs, color match samples, and confirm all details before going to print.

Step 3: Printing & Finishing

Using advanced equipment and color management, we print your graphics to spec. Our finishing team trims, mounts, laminates, and installs hardware to produce a ready-to-install product.

Step 4: Logistics & Coordination

We manage packing, delivery, and site scheduling to ensure everything arrives safely and on time, anywhere in the country.

Step 5: Professional Installation

Our certified crews install your graphics with care and precision, handling every surface and environment with expertise.

Step 6: Support & Refresh

Need updates or replacements down the road? We offer ongoing support, maintenance, and fast reprints to keep your graphics looking fresh.

Compliance, Safety & Quality Standards

We make quality and safety a priority on every project so that you can move forward with peace of mind.

- ADA-compliant signage and graphics

- G7-certified color management for consistent, accurate reproduction

- OSHA-trained installation teams

- Local permitting support for exterior and public-facing projects

- MSDS documentation available for all materials

Who Benefits from Our Large Format Printing?

Our solutions are trusted across a wide range of industries and environments:

- Stadiums & Arenas: banners, seating, sponsor and concourse graphics

- Corporate & Office Spaces: wall murals, branding, wayfinding

- Retail & Shopping Centers: window graphics, POP displays, event signage

- Healthcare Facilities: privacy films, directional graphics, patient-friendly murals

- Educational Campuses: wall and window graphics, donor recognition, signage

- Event & Convention Centers: backdrops, portable displays, temporary graphics

- Transportation: vehicle wraps, fleet graphics, transit advertising

Frequently Asked Questions

How fast can you produce and deliver large-format prints?

Turnaround depends on project size and complexity, but most jobs are completed within 5–10 business days after final artwork approval. Rush services are available, just ask!

Can you help with artwork or graphic design?

Absolutely! Our design team can assist with file prep, layout, and even custom artwork to ensure your graphics look their best.

What materials do you recommend for outdoor applications?

For outdoor use, we suggest high-performance vinyl, mesh, aluminum, or acrylic, often with UV lamination for extra protection.

Can you match my brand's specific colors?

Yes, our G7 color management ensures your brand colors are accurate and consistent across every substrate.

Do you offer installation nationwide?

We do! Craftsmen's certified crews provide professional installation across the U.S. for every type of wide-format project.

Start Your Next Big Project with Craftsmen Industries

It's time to transform your vision into eye-catching, high-impact graphics that set you apart. Whether you need bold banners, immersive murals, or custom signage at scale, our expert team is ready to help, from initial idea to flawless installation.

Don't just imagine what's possible, make it real. Reach out today to discuss your needs, request a free quote, or schedule a site survey.

%202.jpg)