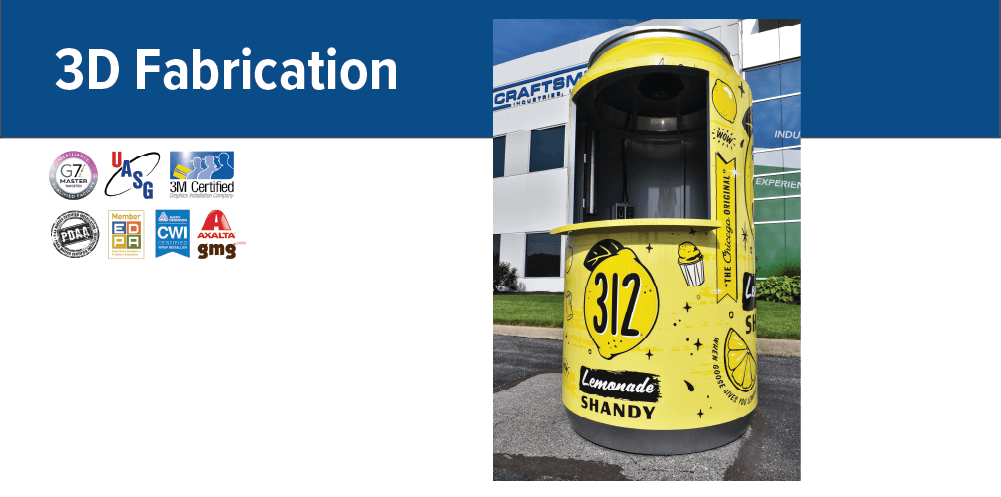

3D Printing

Go Big with our 3D Printing Service

Attract your audience with larger-than-life 3D-printed props. They offer a perfect opportunity for customers to snap a photo to share on social media increasing your impressions.

Our 3D printing service can create large-scale versions of your idea that won't be missed at your event!

Your options are nearly endless - we can 3D print your logo, product, mascot, or whatever you dream up. These 3D pieces are a wow factor at trade shows, product launches, experiential marketing activations, and other special events.

Need some help with a final design? Let's get creative! We have in-house designers that can help with your 3D printing project.

Need a quick turnaround? Our 3D printing technology allows us to create larger-than-life products in a matter of hours!

We also have the capabilities to finish your 3D printed project with sanding, painting, and installation of large-format graphics, so the final product is exactly how you envisioned, all complete within your timeline and budget.

Contact us to find out how Craftsmen

can turn your branding dream into a reality

or Call Today 800.373.3575

Full-Service In-House Graphics Department

Full-Service In-House Graphics Department

"If you want to build the impossible, Craftsmen has the tools and talent. They are more like a Venture partner than a builder."

Founder & CEO

Magicbox

Magicbox

"Craftsmen, hands down, had the best ideas, best drawings. They were as passionate about the project as I was. I don't know why anyone would go anywhere else."

PGA Tour Technician

TaylorMade

TaylorMade

"High caliber work, great crew of talented workers who come up with creative solutions and are easy to work with, overall great partners."

Creative Director

Dairy Farmers of America

Dairy Farmers of America

"The team at Craftsmen is top notch and they always get the job done no matter the deadline. I consider them an extension of our team - a true partner!"

Executive Director

Clayco

Clayco

Request a Quote

Contact Information

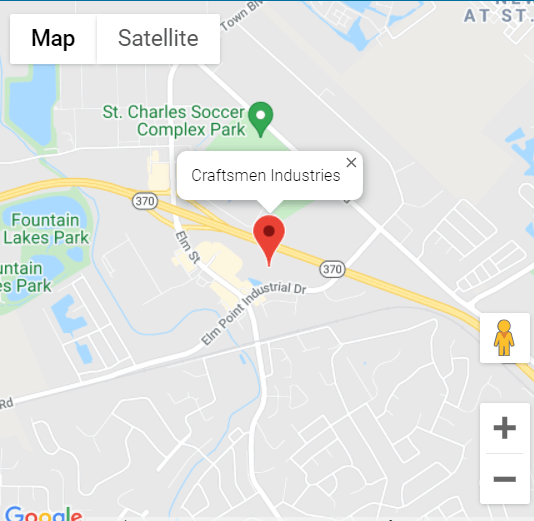

3101 Elm Point Industrial Drive

St. Charles, MO 63301

1.800.373.3575

Contact Us

3D Printing Services: Revolutionizing Manufacturing with Precision & Speed

Craftsmen Industries delivers high-precision 3D printing that cuts lead times by up to 70% and reduces material waste by 90%. We help businesses create complex, custom parts faster and cheaper—transforming ideas into finished products without traditional manufacturing limits.

Make Your Life Easier with Craftsmen 3D Printing Services

Craftsmen Industries offers advanced 3D printing for prototypes and end-use parts with fast turnaround, reduced costs, and high design flexibility. We’re ISO 9001:2015, ISO 13485, and UL certified—trusted across healthcare, aerospace, and regulated industries for precision and compliance.

Types of 3D Printing Technologies Available

3D printing is an additive manufacturing process in which we build objects layer by layer from digital models for you. Here is some brief information about different types of 3D printing services:

Vat Polymerization

Best For: High-detail prototypes, dental models

Materials Used: Standard, Tough, and Flexible Resins

Vat polymerization cures liquid resin using UV light, producing highly detailed and smooth parts. It’s ideal for industries like dentistry and jewelry, where visual precision matters most.

Material Extrusion (FDM/FFF)

Best For: Low-cost prototyping, functional parts

Materials Used: PLA, ABS, PETG, Nylon

Material extrusion feeds thermoplastic filament through a heated nozzle, layering material in a precise path. It’s widely used due to its affordability, accessibility, and broad material compatibility.

Powder Bed Fusion (SLS, DMLS, SLM)

Best For: Aerospace, medical implants, industrial-grade parts

Materials Used: Titanium, Stainless Steel, Aluminum

This process fuses powdered metal or plastic using lasers. It delivers strong, end-use parts with high thermal resistance and mechanical performance—critical for regulated sectors like aerospace and medical.

Material Jetting

Best For: Multi-color, multi-material parts

Materials Used: Photopolymers, Silicones

Material jetting deposits material droplets layer-by-layer and cures them with UV light. It supports full-color and flexible parts, making it perfect for presentation models and product visualization.

Binder Jetting

Best For: Full-color models, sand casting molds

Materials Used: Gypsum, Sand, Metal Powders

Binder jetting sprays a binding agent over powder layers. It's fast, cost-effective, and suitable for casting molds and decorative pieces—especially where mechanical stress isn’t a key requirement.

Our Comprehensive 3D Printing Process

Craftsmen Industries uses a closed-loop production process with a mix of engineering expertise, material science, and project management. Here’s how it works:

1. Design Consultation

- In-house CAD engineers optimize your part for printability and performance

2. File Preparation & Simulation

- STL files are validated with simulation software to check stress points, tolerance, and layer support

3. 3D Printing Execution

- Prints are run on FDM, SLA, SLS, and DMLS printers depending on material and geometry.

- Each printer is calibrated daily and ISO-audited

4. Post-Processing & Finishing

- Craftsmen offers:

- Sanding, vapor smoothing, coating

- Sterilization (for medical parts)

- Painting & branding (for commercial prototypes)

5. Final Quality Control

- Each part undergoes dimensional verification, visual inspection, and material testing (if required).

Craftsmen Industries ensures repeatable results, even across large batches, with documented traceability.

Why Choose Craftsmen Industries for 3D Printing Services?

Craftsmen Industries delivers precision-engineered 3D printing backed by certified quality and rapid production—trusted in regulated, high-performance industries.

Certified Compliance

We’re ISO 9001:2015 and ISO 13485 certified, ensuring every part meets strict aerospace, medical, and industrial manufacturing standards.

Advanced Capabilities

With decades of engineering expertise, we produce high-tolerance, end-use parts and prototypes with complex geometries and fast turnaround.

Custom-Built Solutions

From one-off designs to production runs, we tailor every print to meet your exact specifications, performance requirements, and compliance needs.

Fast, Reliable Delivery

Our streamlined process reduces lead times by up to 70%, delivering quality parts when you need them—without delays or quality trade-offs.

Total Customer Focus

From file prep to final inspection, we ensure clear communication, precision execution, and dependable results at every stage.

How to Choose the Right 3D Printing Services for Your Business With Craftsmen Industries?

Choosing the right 3D printing partner affects product quality, speed, and regulatory compliance. Below are the key decision factors:

Certifications and Quality Systems

A certified provider ensures consistency and compliance. Look for ISO 9001 for quality management or ISO 13485 for medical-grade manufacturing. Craftsmen Industries is also FDA-registered, making it ideal for regulated and high-risk applications.

Material Capabilities

Material range directly affects part performance. Confirm that the provider supports plastics, resins, and metals, including heat- and chemical-resistant options. Craftsmen Industries offers industrial-grade thermoplastics and metals tailored to demanding environments.

Application Specialization

Every industry has unique production needs. Craftsmen serves the automotive, medical, retail, and food service sectors, providing expertise in both functional prototyping and end-use parts with exacting standards.

Post-Processing & Finishing Options

Post-processing affects strength and appearance. Craftsmen offer both cosmetic and functional finishes—from vapor smoothing and dyeing to coatings—ensuring the final product meets both aesthetic and performance goals.

Lead Times and Scalability

Speed and production flexibility matter. Craftsmen deliver 48-hour prototypes and scales quickly using multi-machine systems, unlike hobbyist-focused providers. Their workflow supports enterprise-grade output with high repeatability.

Key Benefits You Will Get From Our 3D Printing Services

Using craftsmen’s 3D printing service offers clear operational and financial advantages:

1. Speed & Efficiency

- We provide rapid prototyping (concept-to-part in hours, not weeks)

- No tooling is required, reducing setup time by 80% (Source: McKinsey.

2. Cost Savings

- We lower material waste (only use needed material)

- Economical for small batches (no minimum order quantity.

3. Design Freedom

- We provide complex internal structures (cooling channels, honeycomb designs)

- Customization at no extra cost (personalized medical devices, bespoke automotive parts)

4. Sustainability

- We reduce our carbon footprint by minimizing scrap and energy use.

- Biodegradable materials (PLA, recycled filaments) are available.

Craftsmen Industries backs its services with engineering support and GMP-compliant environments, especially useful in biotech, pharma, and food-grade applications

Types of Material We Use in 3D Printing Services

Different industries require different materials, each with unique mechanical and chemical attributes.

|

Material |

Properties |

Applications |

|

PLA (Polylactic Acid) |

Biodegradable, low-temp, easy to print |

Prototypes, packaging, education |

|

ABS |

Durable, impact-resistant, cost-effective |

Auto parts, fixtures, electronics housings |

|

PETG |

Water-resistant, strong, clear finish |

Bottles, medical trays, food-grade containers |

|

Nylon (PA12) |

Flexible, wear-resistant, lightweight |

Gears, hinges, and living hinges |

|

TPU |

Flexible, rubber-like, shock-absorbing |

Seals, gaskets, insoles |

|

Carbon Fiber Nylon |

High stiffness, lightweight, tough |

Drone frames, robotics, jigs, and fixtures |

|

ULTEM (PEI) |

Flame-retardant, chemical-resistant |

Aerospace, railway, and medical devices |

|

Titanium (Ti64) |

Lightweight, biocompatible, corrosion-resistant |

Aerospace brackets, surgical implants |

|

Stainless Steel (316L) |

Strong, temperature-resistant |

Industrial tooling, heat exchangers |

Craftsmen offers full traceability of every material batch and complies with RoHS and REACH regulations.

How Long Does 3D Printing Take With Craftsmen?

Lead times vary based on:

- Part size (small items: 30 mins–4 hrs; large builds: 24+ hrs)

- Complexity (supports, hollow sections add time)

- Post-processing (sanding, painting, polishing)

Typical Project Timeline:

- Design & File Prep (1–2 days)

- Printing (6 hrs–3 days)

- Post-processing (1–2 days)

Craftsmen Industries 3D Printing Services Cost

Prices depend on:

✔ Material type (plastics vs. metals)

✔ Part size & volume

✔ Surface finish requirements

✔ Quantity (bulk discounts available)

Estimated Price Ranges:

- Plastic prototypes: $20–$500

- Metal functional parts: $200–$5,000+.

Frequently Asked Questions

- 1. Can 3D printing replace traditional manufacturing?

While ideal for prototypes and complex designs, it’s not yet cost-effective for mass production. Best used alongside CNC, injection molding, or sheet metal fabrication. In hybrid workflows, 3D printing helps shorten the development cycle before final production.

- What’s the strongest 3D-printed material?

Carbon-fiber-infused nylon and titanium alloys offer the highest strength-to-weight ratios for industrial applications. These materials support high-stress applications in aerospace, robotics, and medical tooling.

- Is 3D printing suitable for end-use parts?

Yes—with proper material selection (e.g., ULTEM for aerospace, stainless steel for machinery), printed parts meet functional demands. End-use parts are now common in automotive interiors, electronics housings, and custom medical devices.

- How precise is 3D printing?

Tolerances range from ±0.1 mm (FDM plastics) to ±0.02 mm (SLS metals)—comparable to machining for most applications. Dimensional accuracy depends on calibration, layer height, and print orientation.

- What industries benefit most from 3D printing?

Aerospace (lightweight components), healthcare (custom prosthetics), automotive (rapid tooling), and defense (on-demand spare parts). Architecture, fashion, and consumer goods also adopt 3D printing for agile production.

Need Help Choosing the Right Material or Process?

3D printing bridges the gap between imagination and reality, offering unmatched flexibility, speed, and cost efficiency. Whether you need a prototype, custom tool, or end-use part, this technology delivers precision without compromise.

Talk to a certified 3D print engineer today. Our experts help you reduce costs, increase strength, and streamline time to market—all while staying compliant with industry standards.

The Future of Manufacturing is Craftsmen Industries.

%202.jpg)