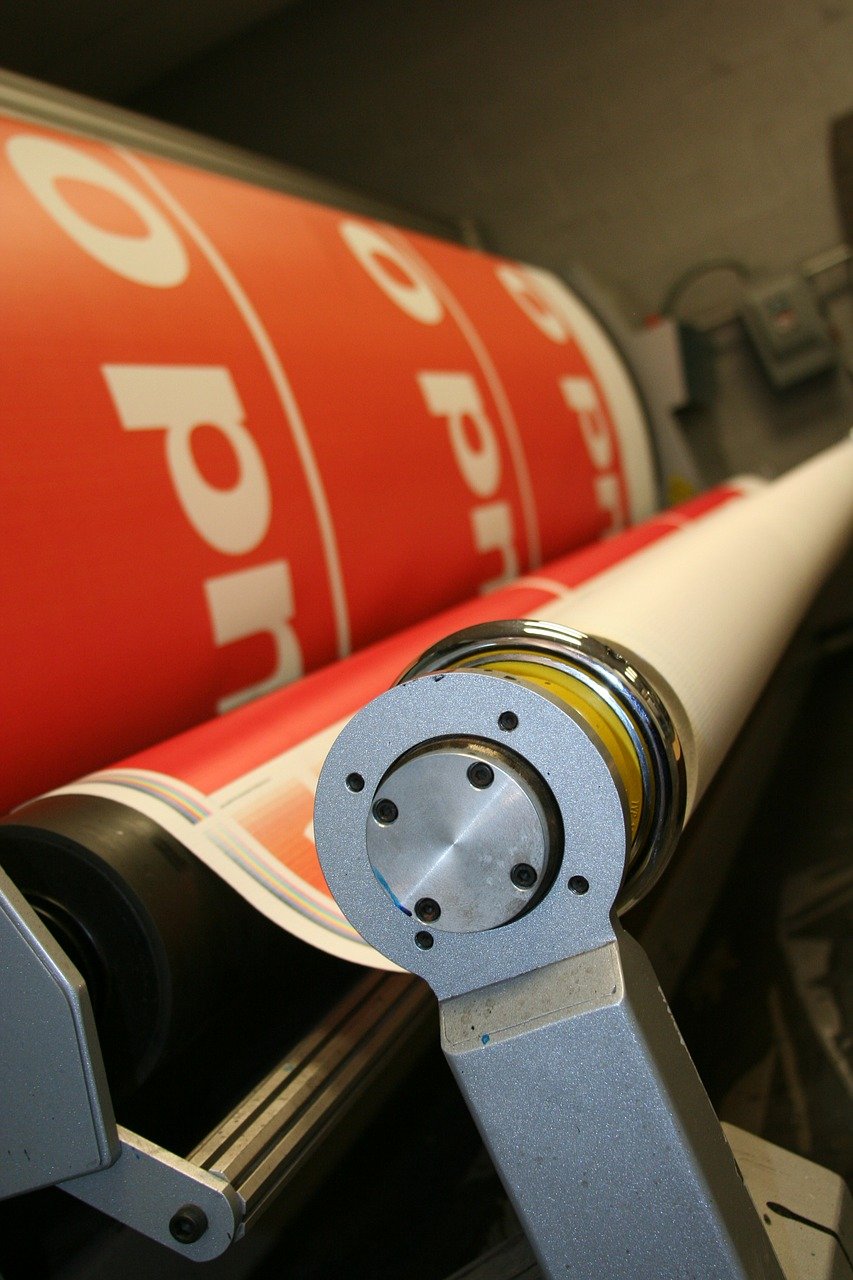

Large Format Printing Ideas for Brand Awareness Campaign

Do you want to maximize the space you use for advertising outside the scope of digital media? Large format printing ideas for brand awareness...

8 min read

Craftsmen Industries Jan 8, 2026 3:38:32 AM

When you step inside a retail store wrapped in dynamic murals or enter an event hall illuminated by vibrant graphics, you’re witnessing the power of well-chosen materials. The quality, texture, and finish of a graphic substrate can make or break an installation.

According to industry insights from Grand View Research, the global large format printing market is projected to reach more than $12 billion by 2030, driven by the growing need for branded spaces, immersive interiors, and high-impact visual communication. This steady growth highlights how important the right materials are when creating indoor large-format graphics that perform well and make a strong impression.

This blog will explore how to choose the best indoor large-format graphics materials, what factors shape that decision, and how expert fabrication ensures every installation looks impeccable and endures through time.

Selecting the right substrate is about more than appearance, as it’s about engineering visual performance to fit the environment. Material choice determines how graphics age, interact with lighting, and maintain color fidelity. Two projects may share the same design but produce completely different impressions depending on the material.

Beyond design aesthetics, decision-making should account for lifespan, environmental conditions, and ink compatibility. Recent industry research shows that sustainability is playing an increasingly important role in sourcing decisions, with over 68% of procurement managers reporting that environmental practices influence their purchasing choices. This shift highlights how material selection has become both a creative and strategic decision, especially for brands focused on responsible design.

Even indoor conditions, such as humidity, light exposure, and airflow, can affect how materials behave. Poorly matched vinyl or adhesive can warp or peel under temperature fluctuations. Choosing materials that are compatible with the space’s lighting and climate ensures reliability and minimizes the need for reprints.

Short-term graphics like pop-up displays call for removable vinyl or paper-based prints, while long-term installations require durable, rigid boards or laminated vinyl. Determining lifespan upfront avoids unnecessary costs or maintenance issues later. Clearly defining the project’s expected duration helps narrow the most suitable material options from the start.

Every substrate interacts uniquely with ink. For example, UV-curable inks sit on the surface for vivid colors, while latex inks absorb slightly for softer, more natural tones. Matching the ink to the material ensures optimal results. Considering how inks and laminates behave on each substrate reduces the risk of surprises during production or installation.

Incompatible ink and substrate combinations can cause dull colors, poor adhesion, or even cracking. Testing samples before full production ensures consistency and durability.

Every indoor graphics project begins with understanding the major material categories. Each substrate offers distinct properties in terms of flexibility, finish, and print quality. Selecting the right one ensures both beauty and function.

The diversity of materials available today reflects major advancements in printing technology. According to research from the National Institute of Standards and Technology (NIST), different substrates can significantly impact color retention, surface durability, and print longevity.

For example, high-quality vinyl and polyester fabrics maintain color vibrancy for several years under indoor conditions, while paper-based materials are better suited for short-term applications. This makes understanding the properties of each material essential for creating durable and visually impactful indoor graphics.

Let's discuss these materials in detail.

Vinyl remains the workhorse of indoor graphics, versatile, affordable, and durable. It comes in permanent and removable types, with matte or gloss finishes that adapt to almost any interior surface. High-quality vinyl car wrap technology is also used indoors for wall applications, offering easy installation and clean removal, minimizing wall damage. Designers rely on vinyl because its broad range of finishes and adhesives match a large variety of spaces and goals.

Soft signage using polyester fabrics or canvas brings sophistication to interiors. Fabric graphics diffuse light evenly, resist wrinkles, and deliver seamless displays in tension frames or SEG systems. Their tactile finish also elevates perceived quality. With textiles, brands can evoke an upscale ambiance while maintaining visual impact across large spans.

For short-term promotions, coated papers provide high print resolution and easy recyclability. They are best suited for campaigns under six months or frequent design rotations. Although less durable than other options, paper media excels when quick turnover and cost efficiency matter most.

Acrylic, foam board, and PVC provide structure for permanent signage and wall panels. Acrylic adds luxurious sheen, while foam board is lightweight and economical. Rigid substrates give installations a premium appearance and ensure the graphic remains flat and stable over time.

PVC-free films and recyclable polyester textiles offer durability without environmental drawbacks, aligning with sustainability goals while maintaining print quality.

Different indoor environments place specific demands on large-format materials. Factors such as foot traffic, lighting, humidity, and airflow affect how graphics perform and age. Selecting the right substrate ensures the installation remains visually accurate, durable, and safe. Considerations include material rigidity, ease of installation, clean removability, and compliance with fire and indoor air quality standards.

To illustrate how these factors influence material choice, here’s a breakdown by application:

In retail spaces, smooth vinyl wall wraps and SEG fabric frames provide vivid imagery with easy refresh cycles. Removable adhesives allow seasonal campaigns to change quickly. Material choices tailored to retail environments help brands keep visuals fresh without compromising surface integrity.

Durable fabrics and PVC boards withstand transport and frequent installation. Their lightweight construction reduces setup time while maintaining professional presentation quality. These materials enable exhibits to move globally while still delivering consistent visual performance.

Textured wall coverings and low-VOC materials enhance brand presence without compromising indoor air quality. They are ideal for hotels, offices, and healthcare settings where safety and ambiance coexist. In these refined environments, materials must complement architecture and contribute to the overall experience.

Materials rated under NFPA 701 comply with fire safety standards for flame resistance, commonly used in hotels, schools, and exhibit halls.

Lighting defines how every printed color is perceived. The same graphic can appear warm, cool, or flat depending on the lighting and finish. Modern research from the Lighting Research Center at Rensselaer Polytechnic Institute shows that ambient lighting has a powerful influence on how color is perceived, often altering its intensity and warmth depending on illumination levels.

Also, according to NIST findings, subtle changes in lighting can significantly affect how surfaces and finishes appear to the human eye. This clearly highlights the importance of careful finish selection and controlled lighting for achieving accurate design accuracy.

What could you have in these choices? Let's have a closer look.

Matte surfaces prevent glare under bright lights, making them ideal for text-heavy or instructional graphics. They also mask surface imperfections. Designers choosing matte finishes help ensure readability and reduce distracting reflections.

Gloss coatings enhance color vibrancy and depth, ideal for photographic or promotional imagery. However, they may reflect overhead lighting in certain settings. When used correctly, gloss finishes deliver high-impact visuals that draw immediate attention.

Canvas-textured vinyl or brushed metal laminates add a tactile dimension. These finishes bring depth and luxury to corporate environments. Textured surfaces invite closer inspection and can elevate the perceived value of the graphic.

The success of any large-format installation depends as much on preparation as material quality. Incorrect adhesives or poor surface prep can cause premature failure. The Occupational Safety and Health Administration notes that improper adhesive handling and inadequate ventilation are common hazards during installations. Proper training, testing, and surface cleaning protect both the material and the workers applying it.

Walls painted with low-VOC paints may resist adhesion. Testing sample patches ensures that the vinyl bonds correctly. Selecting the correct adhesive strength ensures the graphic stays secure without damaging the wall.

Surfaces must be smooth, dry, and free of dust or oils. Even minor contaminants can reduce adhesive strength and cause bubbling. Dedicated cleaning regimes before installation increase the overall lifespan of the graphics.

Expert installers use precision tools and heat application to remove air pockets, ensuring a flawless finish. They use professional-grade materials and tools designed for large-scale applications. Engaging trained installers mitigates risk and ensures the visual intent is faithfully realized.

The diversity of materials available today reflects advances in printing technology. As mentioned in research from NIST, well-maintained and properly selected signage materials significantly improve durability, visual clarity, and environmental performance. This focus on material integrity and ongoing maintenance ensures that printed installations maintain their impact over time, giving brands more creative range and longer-lasting results.

Ideal for pop-ups, trade shows, or seasonal décor. These rely on easy removability and lightweight handling. Using lightweight materials for short-term use reduces shipping costs and simplifies change-out.

Acrylic panels and PVC boards offer years of durability, resisting fading and scratches with protective coatings. Selecting materials built for longevity reduces lifetime cost and safeguards brand investment.

Use non-abrasive cloths and mild detergents to preserve surface integrity. Avoid alcohol-based cleaners that can damage laminates. Regular inspection and gentle cleaning protect the finish and keep graphics looking fresh.

Sustainability has evolved from a design trend into a brand expectation. The Environmental Protection Agency highlights the growing consumer demand for environmentally responsible materials, emphasizing how sustainable choices now influence purchasing behavior across industries.

Choosing PVC-free, recyclable, and low-VOC substrates not only aligns with regulatory guidance but also reflects a brand’s commitment to environmental stewardship, helping businesses build trust and meet the expectations of today’s eco-conscious customers.

Let's explore all possible material choices for indoor large-format graphics.

Water-based inks, polyester textiles, and recycled paper substrates offer vibrant results without harmful emissions. Selecting eco-friendly materials aligns print strategies with corporate sustainability goals.

All materials used indoors should meet fire-rating standards like NFPA 701. Manufacturers should also ensure every product meets or exceeds these safety benchmarks. Compliance integrates seamlessly with design and doesn’t need to disrupt visual ambition.

Choosing substrates compatible with recycling programs reduces environmental waste while maintaining print quality. Working with certified recyclers ensures materials are responsibly handled at the end of their lifecycle.

As visual environments evolve, so do the technologies and design principles behind them. Modern material innovation allows brands to deliver immersive, sustainable, and digitally integrated experiences indoors.

The rise of experiential marketing has made the fusion of technology and material science crucial.

Emerging technologies like photochromic inks and sensor-enabled displays are redefining indoor experiences. These “smart” graphics react to light, temperature, or motion, creating engagement that static prints cannot achieve. The integration of interactivity in printed materials is paving the way for hybrid digital-physical storytelling.

Bio-based films and closed-loop recycling systems are becoming mainstream, reducing the environmental footprint of large-format projects. Many printers now use eco-certified inks to meet sustainability standards. These innovations not only enhance brand responsibility but also attract eco-conscious clients seeking ethical visual solutions.

Advances in 3D texture printing and precision finishing allow for tailored tactile experiences. Designers can replicate wood, fabric, or metallic effects without changing base materials. Such material personalization empowers brands to craft environments that feel exclusive, cohesive, and highly memorable, pushing the boundaries of environmental and architectural graphics.

Choosing materials for indoor large-format graphics requires expertise that balances design, science, and safety. Craftsmen Industries brings decades of experience fabricating and installing high-quality graphic environments, from retail showrooms to corporate interiors. The team’s in-house designers and installers work collaboratively to test, print, and finish every project with precision and compliance in mind.

Whether you need vibrant murals, durable signage, or full-scale experiential environments, Craftsmen’s mastery of materials and processes ensures flawless execution from concept to completion.

Visit Craftsmen Industries to explore tailored large-format and general fabrication solutions that transform interiors into immersive brand experiences built to last.

Graphic overlays are typically made from polycarbonate (PC), polyester (PET), PVC, or acrylic (PMMA) for durability, clarity, and abrasion resistance. Metal and vinyl (often in the form of PVC, or polyvinyl chloride) are also used for specific applications requiring strength or cost-effectiveness.

Getting your vision out there in a big way has never been this simple!

Examples are photographs, drawings, line art, mathematical graphs, line graphs, charts, diagrams, typography, numbers, symbols, geometric designs, maps, engineering drawings, or other images. Graphics often combine text, illustration, and color.

Graphic design is the art of creating visual content to communicate messages effectively. What are the main types of graphic design? The 10 key types are advertising, environmental, publication, motion, corporate, UI, web, packaging, 3D, and information design.

A 'Quality Graphic' is defined as a graphic that retains its high resolution and clarity, ensuring a visually appealing display, even though it may increase the load on the processor of the virtual desktop.

Do you want to maximize the space you use for advertising outside the scope of digital media? Large format printing ideas for brand awareness...

Large graphics can be challenging to design and print, especially if the surface area where they are supposed to be put is not flat. If you have a...

Often, graphics and text printed on an 8.5x11 sheet of paper are just not practical. Text is not readable from more than a couple of feet away, and...