Cost Factors in Fleet Graphics: What Businesses Should Expect

Fleet graphics are professionally designed vinyl wraps or decals that transform company vehicles into mobile advertisements, enhancing brand...

10 min read

Craftsmen Industries Dec 30, 2025 4:38:34 AM

A fleet wrap project involves applying custom-designed graphics to multiple vehicles to create a consistent, professional brand image. It turns each vehicle into a moving billboard representing a company’s identity wherever it travels. For many businesses, a well-executed fleet wrap enhances visibility, builds customer trust, and increases recognition.

According to Statista, outdoor and transit advertising, which includes vehicle wraps, reached over $9.3 billion in ad spending in the United States in 2023, reflecting growing confidence in mobile, real-world brand visibility. This growth shows how fleet wraps play a meaningful role in increasing audience impressions without recurring media costs.

But a project of this scale can feel overwhelming. How do you manage all the moving parts and ensure your investment pays off?

This guide is designed to help you plan and manage your fleet wrap project effectively. We’ll cover how to choose the right vendor, set clear goals, and get the consistent, high-quality results you need to strengthen your brand on the road.

A fleet wrap project requires clear objectives to guide design, production, and installation. Defined goals ensure the project supports brand identity, maintains consistency across vehicles, and meets operational timelines. Proper planning also improves coordination between teams and reduces project delays.

Several core factors shape the planning process, including project goals, fleet details, budgeting, stakeholder input, and risk evaluation. Each element plays a specific role in achieving consistent and reliable wrap results.

These are the key elements involved in planning a fleet wrap project.

Fleet wraps enhance brand visibility, support mobile advertising, and create a uniform appearance across vehicles. Establishing measurable goals provides a foundation for planning and ensures that each wrap aligns with the organization’s visual and marketing standards.

According to a 3M study on fleet graphics, well-executed vehicle wraps can generate millions of brand impressions annually, highlighting their effectiveness as a high-impact, mobile advertising solution.

Project planning begins with an accurate count of vehicles and identification of their types, such as cars, vans, trucks, or trailers. These details determine the scope of production, material requirements, and scheduling. Fleet distribution by region or location also influences logistics and installation planning.

A structured budget and timeline define the project framework. Cost planning covers materials, design, production, and installation, while the schedule outlines the order and timing of vehicle wrapping. Setting these parameters allows consistent progress tracking and ensures all vehicles are completed within the planned period.

Fleet wrap projects involve multiple internal departments. Marketing teams handle brand elements, operations manage schedules, and fleet managers oversee vehicle readiness. Each group contributes specific information required to maintain accuracy and efficiency throughout the project.

Identifying potential risks helps maintain consistency and quality. Common hazards include vehicle downtime, material performance, and installation quality. Early review of these areas ensures proper preparation, reducing the chance of delays or rework during execution.

Fleet wrap projects can face delays, quality issues, or branding inconsistencies if the vendor is not carefully chosen. Each vendor has different skills, materials, and experience, which can directly affect the outcome.

Evaluating vendors thoroughly helps businesses select a partner who can deliver precise designs, high-quality installation, and smooth coordination with fleet operations, ensuring the project runs efficiently and achieves professional results.

Here are the main criteria used to evaluate vendors and clarify the selection process.

Vendors should use durable materials, including premium vinyl with protective coatings suitable for outdoor use. Certifications from recognized organizations, such as 3PDAA or UASG, indicate that the staff is trained and follows industry standards.

Reviewing a vendor’s experience with similar fleet projects, including the types and number of vehicles handled, helps confirm they can manage projects of comparable scale efficiently.

A vendor must be able to adapt designs to different vehicle types and shapes, ensuring a precise fit. Consistency in logos, colors, and overall branding across the fleet is essential for a professional appearance.

Vendors with formal design review processes, mock-ups, and proofing procedures provide a reliable way to confirm that the final full vehicle wraps meet the intended brand standards before installation begins.

Vendors should have a straightforward approach to handling multiple vehicles simultaneously. This includes planning installation schedules, assigning sufficient teams, and covering locations locally or nationwide.

Including quality checks, on-site supervision, and services for removal or future updates ensures smooth operations. A structured logistics plan reduces delays and ensures all vehicles are completed within the project timeline while maintaining consistent quality across the fleet.

Past client references and reviews provide insight into a vendor’s performance and reliability. Clear communication channels, transparent quotes, and organized invoicing support efficient project management. Vendors who document schedules, deliverables, and progress enable project teams to track work accurately, reducing confusion and making it easier to coordinate installations for fleets of any size.

Evaluating vendors should consider the overall value rather than just the lowest price. Important factors include the materials’ durability, the installation’s quality, and the potential need for corrections or rework. Considering additional costs, such as vehicle downtime or repeat applications, helps establish a realistic total project cost and ensures that decisions are based on long-term performance and consistency.

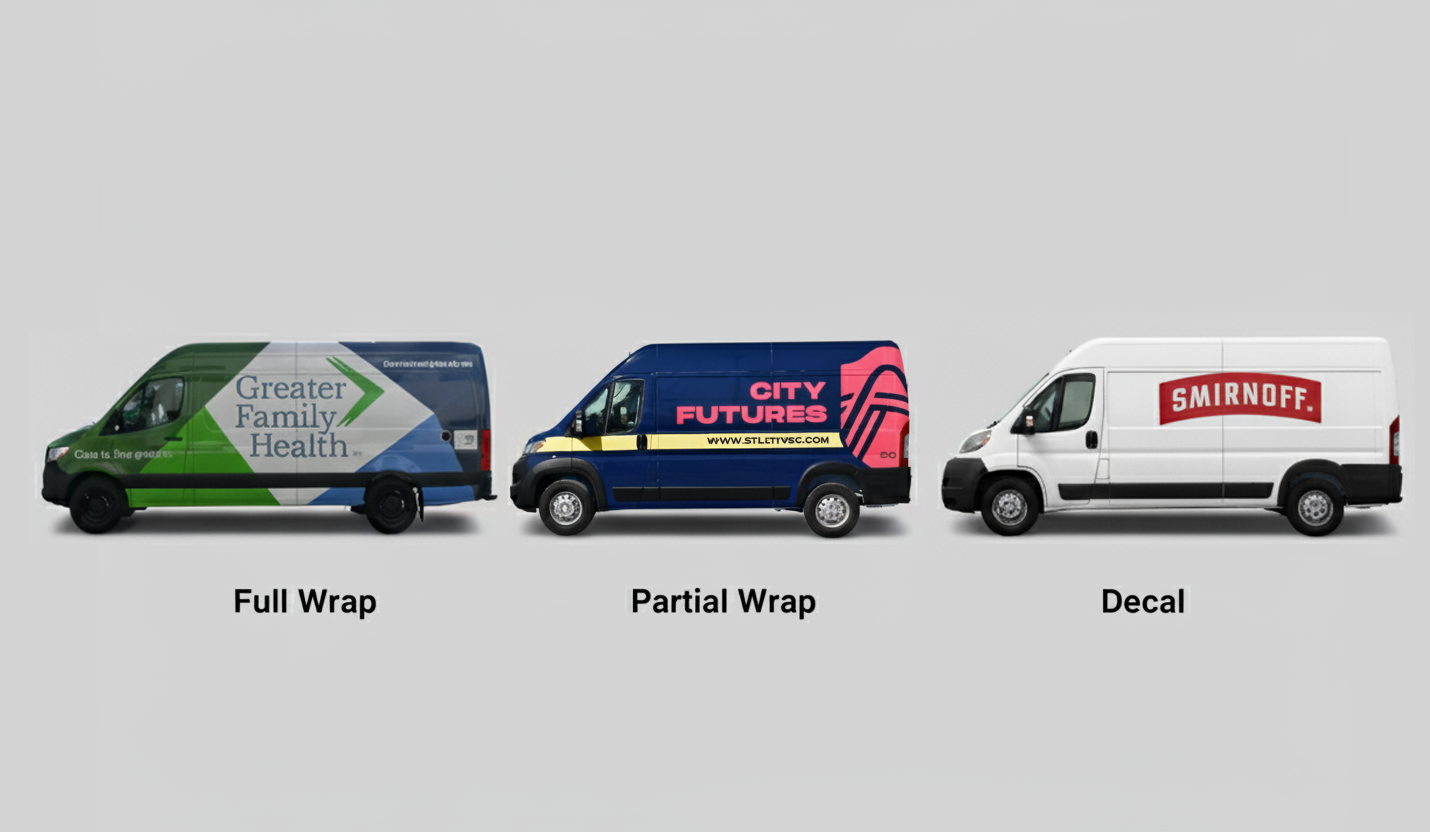

Vendors that can support future fleet expansion or branding updates offer greater flexibility. Services should include partial wraps, decals, or full wraps to accommodate changes in fleet size or brand identity. Scalability ensures that the vendor can meet evolving requirements and maintain consistency across all vehicles, supporting long-term brand presence without switching providers for new projects.

Fleet wrap projects can face delays, cost overruns, or quality issues if responsibilities and expectations are unclear. Have you established which materials will be used, how installations will be scheduled, and the standards that must be met for each vehicle?

A clear contract and detailed project scope provide a roadmap for the entire project. This ensures that all parties understand their roles, timelines, and deliverables, helping to prevent misunderstandings and keep the project on track from start to finish.

The following sections highlight the key components that should be included in a vendor contract and the scope of work.

The project scope outlines the total number and types of vehicles included, whether wraps will be complete or partial cover, and the specific design deliverables. It also establishes the installation schedule, indicating when each vehicle will be wrapped. A clear scope ensures the vendor and client understand the project boundaries, helping coordinate logistics and efficiently track progress across multiple vehicles.

The contract should clearly identify the vinyl brand, lamination type, and expected lifespan of the wrap. Warranty details must be documented to define coverage for defects or premature wear. Including material specifications in the agreement ensures the vendor uses consistent, high-quality products and provides a reference for evaluating performance over time, which supports long-term durability and brand protection.

Quality standards define installation requirements such as seam alignment, bubble prevention, and vehicle protection. Site readiness and preparation are also part of these standards. Setting these criteria in the contract allows for objective evaluation of the vendor’s work, ensuring that each vehicle meets professional standards and that the fleet maintains a uniform appearance across all installations.

Contracts should include measurable performance indicators, including on-time project completion, vehicle downtime, number of vehicles completed per week, and quality rejects. These metrics provide a factual basis for monitoring progress, ensuring the project stays on schedule, and identifying issues early. KPIs create accountability and enable the client and vendor to objectively evaluate the fleet wrap project’s success.

Payment terms cover deposits, milestone payments, and incentives or penalties for project delays or quality issues. Clearly documented terms protect both parties, establishing when payments are due and under what conditions. This structure ensures financial transparency throughout the project and reduces the risk of disputes related to incomplete work, scheduling conflicts, or material performance.

Contracts should outline procedures for handling additional vehicles, scope adjustments, or future refreshes. Including change management protocols ensures that modifications are properly documented and communicated. This allows the project to remain organized even when adjustments occur, maintaining clarity on responsibilities, timelines, and costs without disrupting the overall workflow.

The contract must define the vendor’s responsibility for vehicle damage, accidents, or material defects during installation. Including insurance and liability details ensures that any issues are covered appropriately. This protects the client and vendor and sets clear expectations for handling unexpected incidents, maintaining accountability throughout the fleet wrap project.

Agreements should include guidance on wrap removal, reapplication, and future design updates. Documenting these procedures ensures that maintenance or brand updates are handled systematically. It also clarifies costs, responsibilities, and timing for future work, supporting the long-term consistency and quality of the fleet’s appearance.

Planning and preparing for fleet wrap installation is critical to ensuring consistent quality and minimal disruption to fleet operations. This stage covers everything from auditing vehicles and finalizing designs to coordinating schedules and executing installations precisely. Following OSHA’s vehicle maintenance guidelines ensures each vehicle is properly maintained and ready, reducing the risk of damage during installation. Proper planning helps maintain brand standards, reduces errors, and ensures timely completion across the entire fleet.

Here are the key stages for planning, preparing, and carrying out a fleet wrap project efficiently and effectively.

Documenting the fleet includes measuring each vehicle, photographing conditions, and noting any existing damage. This ensures the vendor has precise information for design and installation. A detailed inventory helps avoid errors, plan materials accurately, and schedule installations efficiently across all vehicle types.

Develop templates for each vehicle type and finalize designs with stakeholder approvals. This ensures the wraps meet brand standards, fit each vehicle correctly, and maintain consistency across the fleet. Pre-approved designs reduce installation delays and prevent costly adjustments after production begins.

Plan window installations around fleet operations, coordinate vehicle availability, and select installation locations. Shipping materials, preparing onsite or offsite setups, and organizing installation teams help ensure smooth workflow. Effective scheduling minimizes downtime and ensures timely completion across multiple vehicles.

Prepare vehicles by cleaning surfaces, repairing damage, and setting up the installation area. Certified applicators follow proper alignment, tension, and seam handling procedures. Proper site preparation supports high-quality, durable wraps while maintaining vehicle safety.

Inspect vehicles after installation, check for bubbles, peeling, or color inconsistencies, and document progress with photos. Use project management tools to track completion across all vehicles. Monitoring ensures that the wraps meet quality standards and any issues are addressed immediately.

Coordinate installation with fleet operations to reduce the time vehicles are out of service. Plan for backups or temporary replacements if needed. Efficient downtime management ensures that fleet operations continue smoothly while installations are completed.

Once fleet wraps are installed, proper post-installation management ensures the wraps’ quality, longevity, and effectiveness. Regular maintenance, monitoring, and planning for future updates keep the fleet visually consistent and professionally branded. This phase also includes evaluating vendor performance to support growth and long-term branding goals.

These activities are essential for successfully maintaining, monitoring, and scaling a fleet wrap project.

After installation, each vehicle should be checked for proper alignment, adhesion, and quality. Document the results with photos and completion checklists. Confirm warranty coverage for materials and workmanship to address defects promptly. This step ensures the fleet maintains a professional look and resolves issues efficiently.

Track key outcomes like brand visibility, wrap durability, and impressions over time. Regular monitoring allows fleet managers to measure the impact of mobile advertising and identify maintenance needs early. Reporting helps guide future campaigns and provides data for planning updates or replacements.

Provide simple instructions for cleaning and protecting wrapped vehicles, such as using mild soap, avoiding harsh brushes, and minimizing prolonged sun exposure. Proper care helps preserve the wrap’s appearance and extends its lifespan. Educating drivers and fleet staff ensures consistent maintenance across all vehicles.

Schedule regular checks to determine when wraps need refreshing or updating, in whole or in part. This ensures the fleet always represents the current branding and maintains a uniform appearance. Early planning for re-wraps helps manage costs and prevents branding inconsistencies.

Evaluate the vendor’s reliability, timeliness, and quality of service after project completion. Use scorecards or review meetings to assess performance and maintain a strong partnership. Planning for fleet growth, additional vehicles, or geographic expansion ensures the vendor can support long-term branding needs.

Fleet wrap projects involve many moving parts, from planning and scheduling to installation and quality checks. Even with careful preparation, everyday challenges can arise that affect timelines, costs, and the overall appearance of your fleet. Awareness of these potential pitfalls helps ensure that every vehicle maintains a professional, consistent, and durable look.

Here are the common issues and ways to keep your project on track.

Selecting a vendor based only on price may compromise material quality or installation standards. Experienced vendors with proven results ensure durable wraps, accurate branding, and fewer corrections. Balancing cost with long-term value helps maintain consistency across the fleet while minimizing the risk of rework and additional expenses.

Poor scheduling or mismanaged vehicle availability can disrupt fleet operations. Planning installation windows around vehicle usage and preparing backup options ensures minimal downtime. Proper coordination helps keep projects on schedule while maintaining normal fleet activities without unnecessary interruptions.

Vehicles must be clean, repaired, and ready before applying vinyl. Dirt, scratches, or paint damage reduce adhesion and shorten the lifespan of wraps. Conducting a detailed audit before installation prevents issues, ensures a smooth application, and preserves the professional appearance of the fleet.

Multi-vehicle projects require careful monitoring. Without tracking, deadlines can be missed and errors can go unnoticed. Simple project management tools or checklists allow teams to maintain quality standards, track installations, and address problems promptly for consistent results across all vehicles.

Wraps have a limited lifespan and may need refreshing or replacing. Establishing agreements for maintenance, updates, or re-wraps ensures ongoing brand consistency. Clear plans reduce surprises, maintain professional standards, and extend the life and impact of your fleet wraps.

Successful installation depends on communication with fleet managers and drivers. Lack of coordination can cause delays or vehicle unavailability. Keeping all parties informed about schedules, responsibilities, and contingencies ensures a smooth workflow and timely completion across the entire fleet.

Successful fleet wrap projects rely on choosing the right vendor and maintaining effective project management at every stage. Careful planning, proper scheduling, and quality oversight ensure that wraps are durable, visually consistent, and aligned with brand standards across all vehicles.

Building a long-term relationship with a reliable vendor adds value beyond a single project, simplifying future updates, re-wraps, and fleet expansions while maintaining high standards and minimizing disruptions. Reviewing contracts and fleet wrap strategies helps businesses prepare for maintenance, branding updates, or growth.

Craftsmen Industries delivers complete fleet wrap solutions, from custom design and precise installation to seamless project management. Whether managing a small fleet or coordinating a large-scale rollout, businesses can trust their expertise to achieve flawless, professional results. Contact Craftsmen Industries to ensure every vehicle reflects your brand at its best, with expert guidance throughout the process to keep projects on track, on time, and visually striking on the road.

Yes. Fleet wrap designs can integrate QR codes, website links, or campaign-specific graphics, allowing vehicles to serve as interactive marketing tools that engage audiences on the move.

Vendors with multiple installation locations or mobile teams can coordinate wrapping services across different regions, ensuring consistent branding and efficient project execution for all vehicles.

Yes. Specialized vinyl materials can create reflective or illuminated effects, improving visibility and safety while maintaining brand messaging on each vehicle.

Minor surface imperfections can often be wrapped, but areas with significant damage should be repaired first. Smooth, clean surfaces provide the best adhesion and long-lasting results.

Modern vinyl offers various colors, finishes, and textures, including matte, gloss, metallic, and chrome options, giving businesses complete flexibility to match their brand identity.

Fleet graphics are professionally designed vinyl wraps or decals that transform company vehicles into mobile advertisements, enhancing brand...

Fleet wraps are far more than decorative graphics. They turn your commercial fleet into a moving marketing channel that promotes your brand 24/7....

Many businesses understand the power of a branded vehicle, but finding a reliable fleet wrap provider nearby can be frustrating. Local shops may lack...